Macchine di rivestimento a rotoli di laboratorio di precisione per la R&S e la produzione pilota di materiali

Dettagli:

| Luogo di origine: | Cina |

| Marca: | OSMANUV |

| Certificazione: | ISO9001 |

| Numero di modello: | OSM-GT-1320 |

| Documento: | Two-roller coating machine.pdf |

Termini di pagamento e spedizione:

| Quantità di ordine minimo: | 1 INSIEME |

|---|---|

| Prezzo: | Negoziabile |

| Imballaggi particolari: | Scatola di legno |

| Tempi di consegna: | 30~45 giorni |

| Termini di pagamento: | T/T |

| Capacità di alimentazione: | negoziazione |

|

Informazioni dettagliate |

|||

| Tipo: | Macchina per asciugatura | Applicazione: | Merce |

|---|---|---|---|

| Materiale da imballaggio: | Legno, plastica, metallo, carta, vetro | Spessore del vetro: | 2 mm |

| Pistola a spruzzo: | adotti la pistola a spruzzo automatica dell'americano GRACO | Larghezza di lavoro effettiva: | 1320 mm |

| Nome prodotto: | Attrezzatura per rivestimento a rulli | Rollermaterial: | Stainless Steel |

| Evidenziare: | macchina di spalmatura a rullo da laboratorio per R&S,apparecchiatura di spalmatura a rullo di precisione per la produzione pilota,macchina di spalmatura a rullo per R&S dei materiali |

||

Descrizione di prodotto

Macchina di rivestimento a rullo di precisione per laboratorio per R&S sui materiali e produzione pilota

-

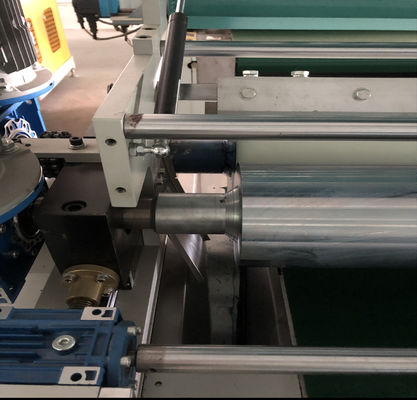

1. Composizione della linea di produzione

Questo sistema modulare è costruito attorno a un'unità di rivestimento principale. La configurazione standard include: stazioni di svolgimento/riavvolgimento manuali, Completamente personalizzabile Modulo testina di rivestimento, gruppo lama dosatrice regolabile, piastra riscaldata (RT-200°C) e telaio da banco. Componenti aggiuntivi opzionali: lampada UV, misuratore di spessore e camera ambientale.

2. Descrizione del prodotto

Progettato per ricercatori e sviluppatori di processi, questo rivestitore su scala di laboratorio consente la replica precisa dei processi di rivestimento a rullo industriali. Il suo design modulare consente di testare rapidamente i parametri di rivestimento, la compatibilità del substrato e le formulazioni dei fluidi con un minimo spreco di materiale, accelerando il passaggio dal laboratorio alla produzione.3. Parametri tecnici

Categoria di parametri Specifiche Larghezza massima del substrato 200 mm, 300 mm (Standard) Lunghezza di rivestimento Fino a 450 mm per passata Intervallo di spessore del film umido 6μm - 500μm (a seconda dell'applicatore) Velocità di rivestimento 2 - 1000 mm/sec (controllo digitale) Opzioni rullo applicatore Asta liscia di precisione, asta Meyer avvolta con filo, Personalizzato Rullo anilox inciso Sistema di riscaldamento Personalizzabile Piastra a temperatura controllata Interfaccia di controllo Controllo digitale della velocità e visualizzazione della temperatura Ingombro della macchina Design compatto da banco (circa 1200 mm L x 600 mm L) 4. Applicazione

Perfetto per R&S, controllo qualità e produzione di piccoli lotti di: Rivestimenti funzionali su lamine metalliche, promotori di adesione su fogli di PVC, inchiostri conduttivi su film flessibili, adesivi sensibili alla pressione e nuove formulazioni di rivestimento.5. Personalizzazione

La macchina è altamente personalizzabile per la flessibilità della ricerca. Gli aspetti personalizzabili chiave includono:-

Testina di rivestimento: Scegli tra sistemi a filiera, asta Meyer o rullo anilox per il tuo fluido specifico.

-

Gestione del substrato: Configura per fogli rigidi, rotoli flessibili o personalizzato piastre di fissaggio.

-

Polimerizzazione: Personalizzabile zone di riscaldamento, integrazione di lampade UV o moduli IR.

-

Acquisizione dati: Integrazione opzionale di sensori per la registrazione di spessore, lucentezza o temperatura.

6. Caratteristica

-

Modulare e aggiornabile: Inizia con una configurazione di base e aggiungi moduli (come la polimerizzazione UV) man mano che le esigenze di ricerca si evolvono.

-

Controllo di precisione: L'azionamento digitale garantisce una velocità di rivestimento ripetibile per dati sperimentali affidabili.

-

Minimo spreco: Richiede solo un piccolo volume di fluido di rivestimento (fino a 5 ml), ideale per materiali sperimentali costosi.

-

Facilità di funzionamento e pulizia: Progettato per un rapido cambio tra i test e una manutenzione semplice.

7. Supporto e servizi

-

Consulenza pre-vendita: Discussione tecnica per configurare il set di moduli ottimale per i tuoi obiettivi di ricerca.

-

Installazione e formazione: Configurazione completa e formazione operativa tramite videochiamata o in loco.

-

Supporto tecnico: Supporto dedicato per i ricercatori, inclusi consigli sull'applicazione.

8. Imballaggio e spedizione

La macchina viene spedita completamente assemblata in una scatola di cartone personalizzata con isolamento in schiuma per la protezione. Spedita in tutto il mondo tramite corriere espresso (DHL, FedEx) per una consegna rapida al tuo laboratorio.9. Domande frequenti

-

D: Questa macchina può simulare il rivestimento a rullo sia in avanti che all'indietro?

R: Sì, selezionando diversi personalizzabile moduli della testina di rivestimento (ad esempio, una testina a rullo a controllo di precisione), è possibile simulare vari metodi di rivestimento industriali. -

D: Quali formati di file accettate per l'incisione personalizzata sui rulli anilox?

R: Possiamo lavorare con file vettoriali standard (.ai, .eps) o disegni CAD per produrre rulli con personalizzato retini e volumi per la tua ricerca. -

D: È adatto per il rivestimento di fanghi o paste con un alto contenuto di solidi?

R: Assolutamente. Il sistema può essere configurato con una testina di rivestimento per pasta per impieghi gravosi, personalizzabile progettata per materiali ad alta viscosità e abrasivi.

-