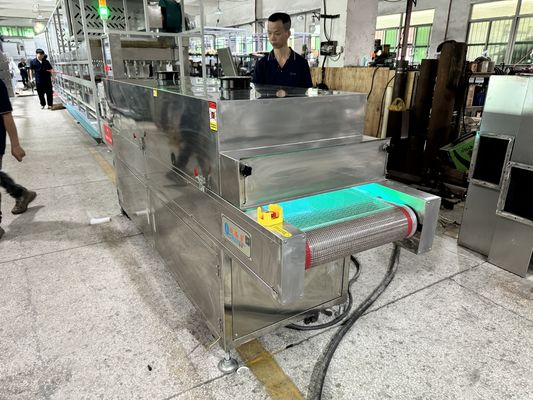

Compact Food Packaging UV Surface Sterilizer | Modular Design Supports Customization

Dettagli:

| Luogo di origine: | Cina |

| Marca: | OSMANUV |

| Certificazione: | ISO9001 |

| Numero di modello: | OSM-SJ-600 |

Termini di pagamento e spedizione:

| Quantità di ordine minimo: | 1 INSIEME |

|---|---|

| Prezzo: | Negoziabile |

| Imballaggi particolari: | scatola di legno |

| Tempi di consegna: | 30~45 giorni |

| Termini di pagamento: | T/T |

| Capacità di alimentazione: | Negoziazione |

|

Informazioni dettagliate |

|||

| Caratteristiche di sicurezza: | Copertura protettiva con interruttore di interblocco | Nome prodotto: | Macchina di irradiazione UV |

|---|---|---|---|

| Tipo: | macchina uv di sterilizzazione | Sicurezza ricoprente: | Alta sicurezza |

| Intervallo di controllo del timer: | 0-99 min | Alimentazione elettrica: | 220 V/50 Hz |

| Lampada di sterilizzazione UV: | Tubo lampada da 30 W(20 pezzi) | Tipo di lampada: | lampada a vapore di mercurio |

Descrizione di prodotto

Vuoi conoscere maggiori dettagli su questo prodotto